High-quality woven labels in Ho Chi Minh City are highly favored by major brands such as Adidas, Nike, and Puma. The primary reason lies in the abundant labor force and Vietnam’s adoption of advanced manufacturing technologies. Clothing labels serve as a brand identifier and provide essential information to consumers. These labels come in various forms, including woven labels, rubber logos, and hang tags. Fashion brands understand that product quality is often judged based on clothing labels. Although different materials can be used for labeling, woven labels remain the most popular choice due to their intricate structure and precise production process, requiring meticulous accuracy down to the millimeter.

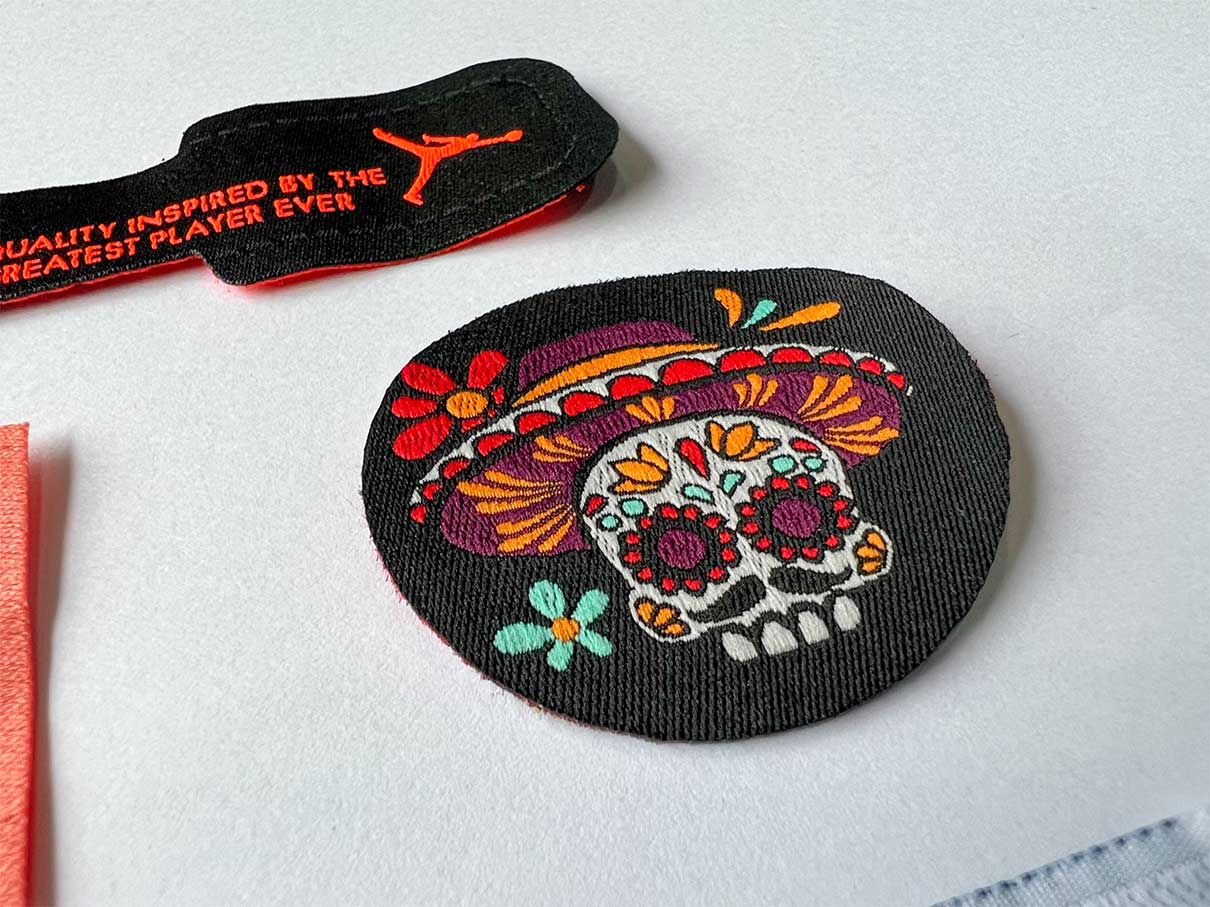

Woven labels have become increasingly popular in shoes, backpacks, and other accessories, helping to define product lines with a unique signature. To enhance brand identity and demonstrate professionalism, many brands choose woven labels as a means to convey their message.

Let’s explore the fascinating world of woven labels with Yung Chang—you might discover something new!

1. Premium woven label production is popular in Ho Chi Minh City.

Ho Chi Minh City is a strategic hub for trade and multi-industry production. With a large workforce migrating from the Mekong Delta, combined with advanced technologies and easy access to raw materials and transportation, the city provides an ideal environment for manufacturing, especially in the textile and garment industry.

Woven labels serve as a lasting signature of a product, accompanying clothing, backpacks, and shoes throughout their lifecycle. Each label carries a brand’s creative message through its unique design. Therefore, the production facility must be well-ventilated and professionally managed to ensure proper storage of both raw materials and finished products, guaranteeing the creation of premium woven labels.

2. What is premium woven label?

A woven label is a small piece of fabric created by weaving threads together using specialized weaving machines in manufacturing facilities. Woven labels contain important product information that brands want to convey to consumers, such as logos, slogans, company websites, and, most commonly, washing and care instructions. Like a unique identity, brands incorporate specific colors, fonts, sizes, and shapes into woven labels to create a distinctive mark for their products.

Woven labels are favored for their soft feel, reducing itchiness and irritation caused by labels rubbing against the skin. With specialized weaving techniques, high-quality woven labels maintain their shape even after multiple washes. Premium woven labels in Ho Chi Minh City are highly preferred due to the application of advanced and modern technologies, ensuring softness and durability.

3. Common Types of Woven Labels

3.1 Satin Background Woven Label

It is a term referring to a weaving technique that uses 100% polyester threads on specialized weaving machines. This technique creates a glossy, soft, and smooth surface on one or both sides of the woven label. Notably, it eliminates the mirror reflection effect (reversed text on the back), which can reduce the aesthetic appeal of woven labels. The softness of satin background woven labels makes them a top choice for safety and aesthetics, widely used by fashion brands for baby clothing and elegant, luxurious outfits.

3.2 High-Density Woven Label

It is a weaving technique that interlaces the background threads with the threads of the font or other content on the woven label. High-density woven labels are firm, sharp, and have a higher stitch count per unit area than usual, allowing all types of fonts to be woven. As a result, they are widely used in the fashion industry. Although not as soft as satin woven labels, they still ensure safety when used on children’s clothing and for individuals with sensitive skin.

3.3 Standard-Density Woven Labels

Similar to high-density weaving techniques but with fewer stitches and lower-quality materials, standard-density woven labels are prone to deformation and fraying after repeated washes. These are budget-friendly labels suitable for products that do not require high aesthetic appeal but still need to convey essential information to users.

4. Advantages and Disadvantages of Woven Labels

4.1 Advantages of Premium Woven Labels

Premium woven labels must meet several quality requirements, at least three out of the four criteria below:

- Durability and Smoothness: Thanks to specialized weaving techniques, the label base is sturdy and thick, ensuring the design remains intact.

- High Longevity: Customizable thread colors and materials create special weaving effects while maintaining colorfastness over time.

- Luxury and Professionalism: Woven labels add value to a product, so manufacturers must pay attention to every detail to meet brand requirements.

- Custom Shapes: Labels can be cut into various shapes based on customer specifications.

4.2 Disadvantages of Woven Labels

Despite their many advantages, woven labels have drawbacks, most notably their cost and production time, which can take 5–10 days to complete.

5. Woven Label Specifications

Brands should carefully consider label dimensions before requesting designs to ensure accuracy. The standard length and size of woven labels depend on the type of woven base—satin, high-density, or standard-density—since each type has a different thread capacity. Cutting and folding processes also impact the label’s aesthetics. Clients should communicate directly with manufacturers to ensure the appropriate dimensions.

The label size depends on the design and content the brand wants to convey. The weaving technique used determines the label’s specifications and length. Cutting and folding also play a crucial role in the final appearance of woven labels. Clients should work closely with manufacturers to achieve the best results.

6. Sản xuất nhãn dệt cao cấp riêng biệt cho thương hiệu của bạn ở đâu?

Yung Chang Viet Nam is a leading manufacturer specializing in high-quality woven labels with over 20 years of experience. Besides producing garment labels, Yung Chang is an officially designated manufacturer of woven labels for shoes, sandals, backpacks, and other fashion accessories for major brands such as Adidas, Puma, and Nike…

Thread color is a crucial factor in determining product quality. Yung Chang is equipped with in-house dyeing machines that can achieve color accuracy of 85–90% to match design specifications. To earn the trust of top brands, we meticulously oversee and expedite production processes to ensure timely completion. Yung Chang’s ultimate goal is to meet both production volume and quality standards.

CONCLUSION

We hope this article helps you better understand woven labels and their significance in the fashion industry.

Tiếng Việt

Tiếng Việt 中文 (台灣)

中文 (台灣)